21 Sep Wind propulsion innovations in maritime navigation

In March 2021, we could see the world stop with the container ship Ever-Given in the Suez Canal. This blockage has revealed important economic issues. With thousands of container ships sailing the world’s oceans, the risks are not only economic but also environmental. Today, 90% of international trade is carried out via shipping. Maritime transport is the second most carbon-intensive sector in the world after electricity production. With over 25% of CO2 emissions, freight transport is constantly increasing. New technologies appear to reduce CO2 emissions, in particular through the use of wind propulsion.

Purpose : reducing the carbon impact of the merchant navy !

These ships use a lot of fuel such as heavy fuel oil which, in addition to emitting CO2, emits sulfur. There is a strong appeal to reduce fossil fuel consumption. Various solutions have been implemented to reduce and/or replace the use of this fuel. Nowadays, more and more cargo ships sail on LNG (liquefied natural gas) and soon on hydrogen.

Other innovations are under development, such as the use of sails to limit the carbon impact due to climate issues. LCJ Capteurs wishes to highlight several actors in the design of sails for cargo ships and thus share information related to the sail energy.

What are the different technologies of wind propulsion?

Due climatic stakes, the navigation by the wind is one of the green solutions to reduce the ecological impact. Different technologies have been improved by the wind propulsion. To support these approaches, the International Windship Association was created. It gathers several innovative actors in wind energy.

The International Windship Association classifies wind propulsion technologies into 7 different categories:

- Soft Sail – between traditional sails and new dynarig (square rig shape) designs, etc.

- Hard Sail – such as thick airplane wing sails, thin 3D pre-stressed sails, etc.

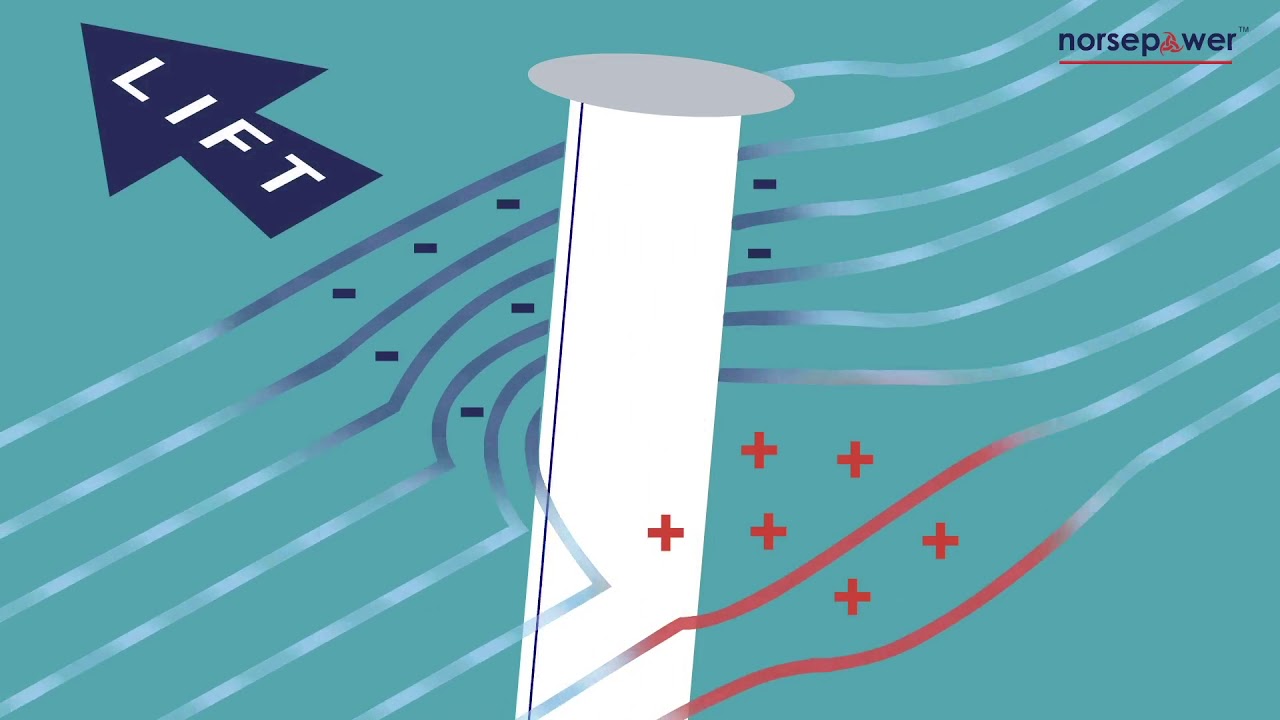

- Flettner Rotor (Rotor Rotor) – Rotating cylinders driven by low-power motors using the Magnus effect to generate thrust.

- Suction Wings (Ventifoil, Turbosail) – Non-rotating wings with internal vents and fans (or other devices) using suction in the boundary layer to achieve maximum effect.

- Kites sails – dynamic or passive at the front of the vessel to facilitate propulsion or generate a mixture of thrust and electrical power.

- Turbines – using adapted marine wind turbines to generate electrical power or a combination of electrical power and thrust.

- Hull form – the redesign of the upper part of ship hulls to capture the force of the wind and generate thrust.

Oceanbird project, the future luxury cargo ship ?

The Oceanbird project, under development at the Swedish university KTH and in collaboration with the shipping company Wallenius Marine, is about to be launched.

The prototype has been developed by ten PhD students from all over the world. However, the project was delayed due to sanitary restrictions.

At the end of 2020, tests of the model of the future Swedish cargo ship were conducted in the Stockholm archipelago. The aim of these tests is to analyze the wind flow around the rigid telecospic sails and how to optimally adjust the route according to the dominant wind conditions

Oceanbird prototype uses CV7-E-OEM ultrasonic wind sensors

The prototype consists of 4 retractable sails, with CV7-E-OEM ultrasonic wind sensors supplied by LCJ Capteurs.

The shipping company Wallenius Marine wants to bring back the use of wind energy in freight transport. To achieve this, it promises to cross the Atlantic in 12 days instead of 8 days and to reduce emissions by 90%.

By comparison, the world’s largest cargo ships carry more than 47,510 cars, while the Oceanbird will carry “only” 7,000 vehicles. It is 200 meters long, but the largest cargo ships are 400 meters long. Designed for a load of 32,000 tons of cargo, while the MSC Gülsün, the largest cargo ship in the world, can carry over 20,000 containers.

It is possible that the Oceanbird also operates as a cruise ship.

Oceanbird’s final project would be to have four large sails, each one hundred meters high. These sails will absorb the wind and propel the ship forward. The sails will be masts that can be lowered to go below decks and adapt the sails to the wind. These masts-sails will be able to be lowered to a height of 50 meters, which represents a real technological feat. Also called telescopes, they will facilitate navigation operations in narrow harbors.

From prototype to production : a real challenge !

The transition from prototype to final construction is a crucial step. If some elements are easy to expand such as mass, stability and length, other elements such as aerodynamic and hydrodynamic effects are more difficult steps to dimension correctly. In fact, at full size, the ship will absorb wave generation, wind speed and incoming sea waves differently. The mechanical parts, such as the wings and rudders, which go deeper into the water, may have a lot of changes in terms of relief.

There are still many challenges ahead for OceanBird engineers. They hope to have the first full-scale ship sailing within four to five years.

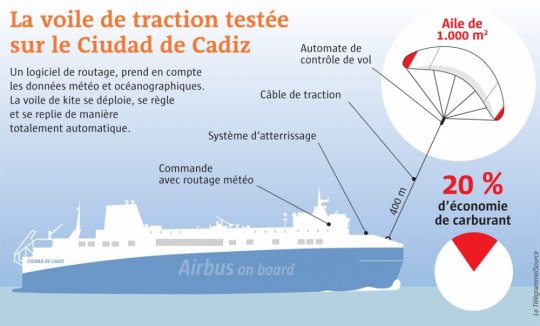

Airseas : the fuel-saving kite sail

Airseas, the Nantes-based Airbus spin-off (formerly from Toulouse), has unveiled its innovation that consists of saving 20 to 40% of fuel on container ships and thus considerably reducing greenhouse gas emissions. It is a giant kite sail that tows commercial ships. This kite propulsion technology, filled with sensors and radars, is not only intended for maritime transport but also to be used in the Airbus aeronautics. This innovative wing is called the Seawing and is expected to be commercialized in 2021.

Some figures to understand the scope of the project

Before the health crisis, more than 150 engineers were working on this project and 7 patents were registered for the system of folding and unfolding the sail. This 1000 m² sail is hoisted on top of a 30 to 35 meters mast. It is held in place by cables at a height of 150 meters and will be able to pull with a force of up to 100 tons ships that are 200,000 tons and 300 meters long.

How does Airseas Seawing technology work?

The Seawing’s dynamic technology is controlled by a navigation system inspired by aeronautics. The retracted Seawing takes the place of a simple 5 x 5 meter container. Its automatic 15-minute deployment is done when the decision support software indicates the best weather conditions. For this type of technology, many sensors were used, including several LCJ Capteurs ‘ ultrasonic wind vane-anemometers :

- CV7-E,

- CV3F,

- CV3F-AL,

- CV7-V.

All the sensors and software will allow the system to predict the storm and automatically fold the sail. The Seawing sail will be able to sail in winds of up to 40 knots (75 km/h) and is activated at 8 knots (15 km/h).

Seawing technology already tested at sea?

Several tests have been carried out, including one in 2018 on the vessel “Ciudad de Cadiz”. This French ro-ro ship provides maritime logistics for Airbus. The “Ville de Bordeaux” is also fitted with a 500m² sail from the Airbus spin-off. It should cross the Atlantic between France and the United States next November.

The Seawing is an example of how Airseas is applying aerospace engineering to make the shipping industry a more efficient and cleaner option.

Zéphyr et Borée: the first modern sailing cargo ship!

The Nantes-based company Zéphyr & Borée, a member of the Atlanpole network, has already proven itself with Jifmar on the Canopée Project proposed by Ariane Groupe, for the transport of the Ariane 6 rocket.

In 2020, always in search of innovation, Zephyr & Borée wants to develop the world’s first rigid sail container ship. The project, named Meltem, would be a container ship 185 meters long and 31 meters wide, equipped with 8 rigid wings. Their ambition is to reduce the carbon footprint by 80% on a transatlantic journey.

The Meltem Project: an unrealistic project?

However, this project faces many technical complexities. Indeed, the addition of sails represents a problem in terms of logistics, for loading operations, but also for visibility on the front. However, Zéphyr & Borée meets a market need: to support companies committed to decarbonizing their supply chain by transporting their products in containers.

The use of sails on cargo ships has often been considered unrealistic. But following the creation of their ro-ro ship, Zéphyr & Borée is making sail power on cargo ships increasingly credible.

Towt : the Breton company and its cargo sailboat

TOWT is an abbreviation of “Transoceanic Wind Transport”. This company, created in Brittany by Guillaume Le Grand from Brest and Diana Mesa from Bogoté in 2009, is a sailing transport company based on an eco-responsible and zero-carbon approach.

Since 2009, TOWT has been transporting goods over distances between France and Great Britain, the Netherlands and Scandinavia. Environmental issues are a real concern in these countries, as well as in France. The company works in collaboration with several sailing ships for their delivery.

“Phoenix”, the promising cargo sailboat in its ecoresponsible approach.

This company is planning to create its own “cargo sailing ship”, a logistical alternative to conventional container ships. Always in an eco-responsible approach, the “Phoenix” project could save more than 10,000 tons of CO2 per year. Phoenix will be able to transport 1,000 tons of goods with its 67 meters length. As fast as a current container ship (11 knots), this project is optimized in terms of reliability, costs, environmental transparency, commercial and marketing impact.

By this means, TOWT wishes to compete with cargo ships with high CO2 emissions and to propose an offer linked to sustainable development values with eco-ships.

Neoline : a future already mapped out in wind propulsion!

The Neoliner is a ro-ro cargo ship with diesel-electric auxiliary propulsion. It will be able to carry the equivalent of 280 containers with its 136m length. Neoline’s first vessel will soon see the light of day, as they have signed an agreement on the design and construction with the Neopolia group of companies from the Loire Valley.

Its 4,200 m² of sails will enable it to navigate at a commercial speed of 11 knots, where a motor vessel navigates at 15 knots. This will save 80% to 90% of fuel.

The cargo ship will have a diesel electric engine to perform maneuvers in the port. It will be able to pass under bridges of 41 meters in height thanks to a system of folding masts. A crew of fourteen men will be enough to pilot the Neoliner. The route has already been calculated so that the Neoliner will make two rotations per month between Saint-Nazaire, Bilbao and the United States (Charleston and Baltimore). For its return trip, the Neoliner will pass through Saint Pierre and Miquelon.

Neoline, a decision aid for funders

This new style of cargo ship is being negotiated with the financiers and the shipyard. The announcement of new clients is an aid to decision making for the financiers. Indeed, some of the most renowned companies will benefit from the services of the Neoliner such as :

- Clarins,

- the Bénéteau group,

- the Renault Group,

- Manitou Group,

- Jas Hennessy & Co.

Norsepower, rotor sails for everyone!

Credit : Norsepower

Unlike its colleagues, Norsepower does not propose the design of an entire vessel dedicated to the wind propulsion. Their solution is to propose rotor sails on existing vessels. Rotors, a technology developed by Anton Flettner in 1924, are rotating cylinders with small motors to generate thrust (as defined by Energie de la Mer). For this purpose, the Magnus effect is used, i.e. the difference in air pressure on the different sides of a rotating object.

The Norsepower rotor sail is an improvement of Anton Flettner’s technology. Produced with lightweight composite materials, its operation is fully automated such as a control equipment that detects the effect of wind on fuel economy. The crew can fully control the rotor, which starts by itself.

This solution is recommended for high utilization vessels, open decks and trade routes in favorable wind areas.

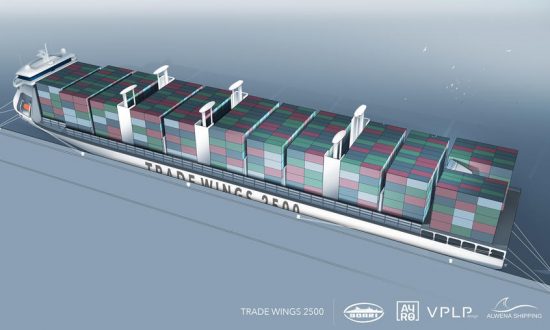

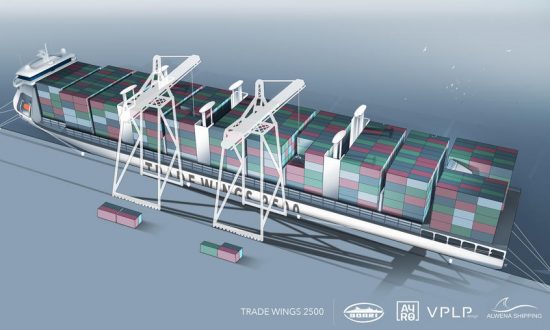

Tradewinds 2500 : high performance mast-wings

According to the media Jeune Marine, the Trade Wings 2500 is an innovative container ship with a length of 197m and a width of 32m. The vessel will be able to carry up to 32,500 tons, with a capacity of 2,500 TEU (Twenty Foot Equivalent Unit).

This container ship project is designed in cooperation by VPLP Design (France), Alwena Shipping (France), SDARI (China) and AYRO (France).

It combines two different technologies for its propulsion, one is for hybridization with Oceanwings and the other with an LNG-diesel electric engine with pods. The mast-wings have a retracting mechanism. A concept created by VPLP Design that proved itself in 2009 when Oracle won the America’s Cup with this innovation. For the Tradewinds 2500, the technology is adapted so that these masts can be partially removed in port, to facilitate commercial operations. Today, CNIM is industrializing this solution for shipping vessels like the Tradewinds 2500.

These engines reduce CO2 emissions by 35% compared to a conventional ship, 57% of which is due to Oceanwings.

Credit : AYRO

Skysails, the kite that works like a wind turbine.

The German group Skysails is not at its first attempts in terms of developing a technology for wind energy. Indeed, born in 2001, the company created a giant kite for the container ship MS Beluga SkySails. Nevertheless, the ship owner went bankrupt in 2008.

But Skysails didn’t stop there and continued to work on kite propulsion. It is thus 10 years later that it is directed in the design of a kite of towing. The goal of this technology is to exploit the powerful winds at more than 400 meters of altitude and to produce more energy than with traditional turbines.

How does the Skysails flying wind turbine work?

This flying wind turbine works on the principle of a kite like an inverted “yoyo”. Linked by a cable to a winch, the kite flies at an altitude between 200 and 800 meters. During this flight, the kite will establish a figure eight circuit in the sky. This resistance creates a pull on the winch placed at the top of the take-off mast. This force exerted by the kite will generate electricity via an alternator at the end. When the wing reaches its maximum altitude, it is brought back to the vessel by the winch.

During the descent of the wing, which is positioned for a minimum of wind load, the generator acts as an engine and consumes power. But only a small part of the energy produced during the first phase is used. The duration of each cycle is variable between two and three minutes. The whole process is automated, which does not require any intervention from the crew.

Skysails’ technology uses LCJ Capteurs’ CV7-E-OEM ultrasonic wind sensors. This high-speed ultrasonic wind vane-anemometer is perfect for integrators. The data is processed by a PC or by one of the development kits such as Arduino, Raspberry, etc. This sensor is easily programmable and configurable for alignment, smoothing time constant, measurement units and interface format.

Anemoi: Rotors Sails on rails?

The British company Anemoi is a direct competitor to the previously mentioned Norsepower. Their wind propulsion technology is also based on that of the German Flettner in the 1920s. Anemoi’s rotor sails will see the light of day in mid-2022 on the bulk carrier TR Lady in China. The vessel is 229m long and 32m wide. The TR Lady was built in China in 2017.

Unlike Norsepower where the rotor sails will be partially obliterated, Anemoi will put the rotors on rails to facilitate port loading.

Blue Planet Shipping’s Afros vessel equipped with Anemoi’s Rotor Sails

Anemoi is not new to the TR Lady, as they had equipped the Afros vessel in 2018. The Blue Planet Shipping vessel is a 199-meter bulk carrier on which the rotor sails are tiltable. The returns from this technology allow the Afros to reduce its consumption and emissions between 5 and 30%.

In 2018, Blue Planet Shipping was ahead of its time by offering the first bulk carrier with a part of the vessel in wind propulsion. This system allowed the vessel to be efficient in terms of speed, cost and fuel consumption. The company Lloyd’s list voted the Afros as “Ship of the Year” in 2018.

Grain de Sail : the first Breton sailing cargo ship for coffee and chocolate?

Born in Morlaix in 2010, the company Grain de Sail was born with a bold idea: importing coffee and chocolate from the other side of the world while limiting CO2 emissions to a maximum.

Starting with the commercialization of these products, opening a first coffee roasting workshop in 2013 and a chocolate factory in 2016, Grain de Sail touches their final goal: the construction of their first cargo sailing boat.

After 2 years of construction, it is in 2020 that Grain de Sail will see their ship leave the shipyard. In November 2020, it is their first transatlantic adventure to develop their business of selling organic chocolates and coffees made in Brittany.

To avoid empty crossings, they started in 2016 to export exceptional French organic wine to the United States, especially New York. To then continue on to Latin America, the 24-meter cargo sailboat is loaded with cocoa and coffee seed raw materials for a maximum air-conditioned capacity of 50 tons. The sailing ship ends its 3-4 month journey in Brittany via the Azores.

A beautiful activity in full expansion where the values of the taste, the adventure and the sustainable development are well with the appointment!

Aquarius Marine Renewable Energy : solar and wind energy mix ?

Aquarius Marine Renewable Energy (Aquarius MRE) of Fukuoka, Japan, is reinventing sails with a system that integrates photovoltaic panels on rigid sails. The Japanese company combines solar energy and sail propulsion with energy storage modules and a charging system.

Their technology, called Energy Sail, proposes a wind propulsion system with an automated sail. It will position itself according to wind conditions and will have a function to lower itself and store in case of bad weather.

Aquarius MRE assures that this assisted propulsion system can be adapted to “a wide variety of vessels”:

- Bulk carriers,

- Ro-ro ships,

- Cruise ships,

- Ferries,

- Oil tankers,

- or even military vessels.

The company’s objective, without giving any figures, is to reduce carbon dioxide emissions.

Silenseas: a concept between yacht and cruise ship from Chantier de l’Atlantique

The Chantier de l’Atlantic in Saint-Nazaire is also unveiling its 2018 ship project at the international show: Silenseas.

This concept is a mix between a yacht and a cruise ship. With respected dimensions, the Silenseas will sail in the most exclusive areas in the world. The sails will bring comfort to the passengers:

- no engine noise,

- no vibration,

- satisfaction of traveling in a cruise close to “zero emission”.

Silenseas: there’s no stopping the innovation of wind propulsion!

The Silenseas will be 190m long with strong and durable sails made of composite material. Through its Solid Sail innovation, the vessel will operate in most wind conditions. The sail will remain deployed even when the engines are running to maintain the desired speed. The chantier de l’Atlantique has a thriving R&D activity with its Solid Sail innovation, but also its Aeol Drive technology, which includes a 360° steerable balestron. All of these innovations significantly reduce emissions and operating costs.

With the sails, the ship is equipped with dual-fuel engines to meet its cruising schedule. Its engines, associated with the sails, will respect the next requirements of the regulation in terms of greenhouse gas emissions of the European Green Deal/.

In 2021, various tests are underway, including a 1/5 scale model. These tests will confirm or not the maturity of the project and the possibility of deployment on other applications.

Michelin Group unveils its WISAMO project: inflatable sails.

International specialist in tires and concerned about sustainable mobility, the Michelin group unveils its interest in freight transport in June 2021. Indeed, Michelin innovates in wind propulsion with their Wisamo project, a contraction of “wings sails” and “mobility”.

Wisamo is an inflatable sail that would save between 10 and 20% of fuel on freighters. These sails could be install on new ships but also those in operation. The objective is to reduce CO2 emissions from maritime transport.

The beginning of a massive change in shipping?

Shipping industry is under multiple pressures from a growing and highly competitive market. On the other hand, the market players are driven to adhere to the ever increasing environmental requirements.

These players are proposing solutions that are integrated or can be integrated into older ships. The objective is to be able to reduce fossil fuel expenses in order to remain competitive and have a greener navigation.

In the long term, we can now hope to see more ships running solely on green energies thanks to wind propulsion. For the time being, the use of 100 % wind propulsion in maritime transport is not feasible because sailing is too approximate for the logistic organization of the large ports of exchange.

The approach to reduce the environmental impact remains the objective of each actor who has created solutions.

The various sailing cargo ships represent a technology with wind propulsion in full development. Other innovations are emerging in relation to the wind such as SeawitLab who propose 3D textile wings. This new technology is not yet integrated in sailing cargo ships. But we are looking forward to see the development of new technologies in the coming years. Discover in details other projects on the Wind Ship website.

Sources

Silenseas

Anemoi

Tradewings

General Information